The inside of classic radios retains wonders that the chips that are sterile and SMD components of today’s circuits can’t hold a candle . Chunky resistors and capacitors, vacuum tubes together using cathodes aglow, and seemingly free-form loops of cable forming inductors will all likely make an appearance. However, the most fascinating bit of any old radio was attached to the tuning knob: the massive variable capacitor using its interdigitating alloy plates. Watching one in the office, using its plates evenly and finely spaced, is still a joy to behold.

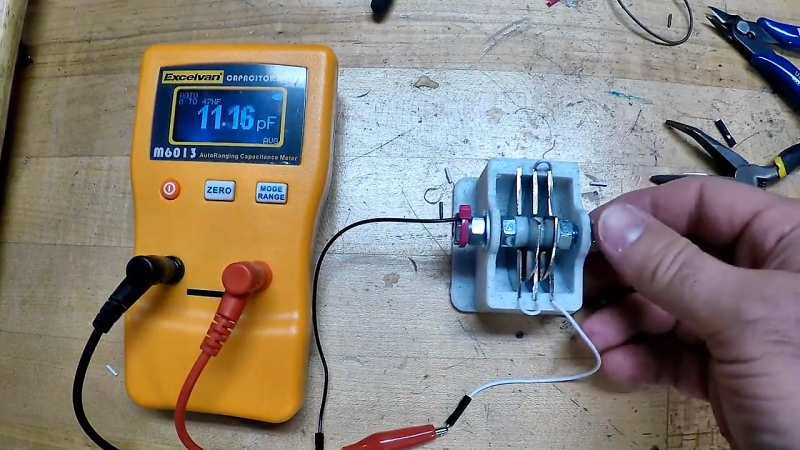

In an effort to recapture a little of the magical, [Jeremy S. Cook] came up with that this home-brew variable tuning capacitor. The framework is built mainly from 3D-printed parts, which affirms a shaft produced from a frequent bolt. Plates are fashioned from stainless steel fender washers cut ; the fixed plates are press-fit into the framework whereas the rotary plates ride onto the rotating shaft. The spacing between the nut discs is maintained by published spacers, which also function to lock the rotor into a strong unit. [Jeremy]’s prototype, for he provides STL documents , could be tuned between approximately 7 and 15 pF. Check out the build in the movie below.

We adore the appearance of this, and we can envision custom tuning caps will come in handy for certain retro radio builds. The tuning range is a little thin, however that could be mended with more plates or even closer spacing. This might be a tall order with thick steel cans, but we all ’ve seen very lean aluminum machined and closely spaced before, therefore this might be one solution to greater capacitance.

Due to [Baldpower] for the tip.

Buy Tickets for every event – Sports, Concerts, Festivals and more buytickets.com

Leave a Reply

You must be logged in to post a comment.