3D printing company Seurat is named after pointillist painter Seurat becausehe, the business wants to work pixel by pixel. Rather than follow a laser within the entire build, they would like to illuminate and heat each pixel of this layer at once for faster results.

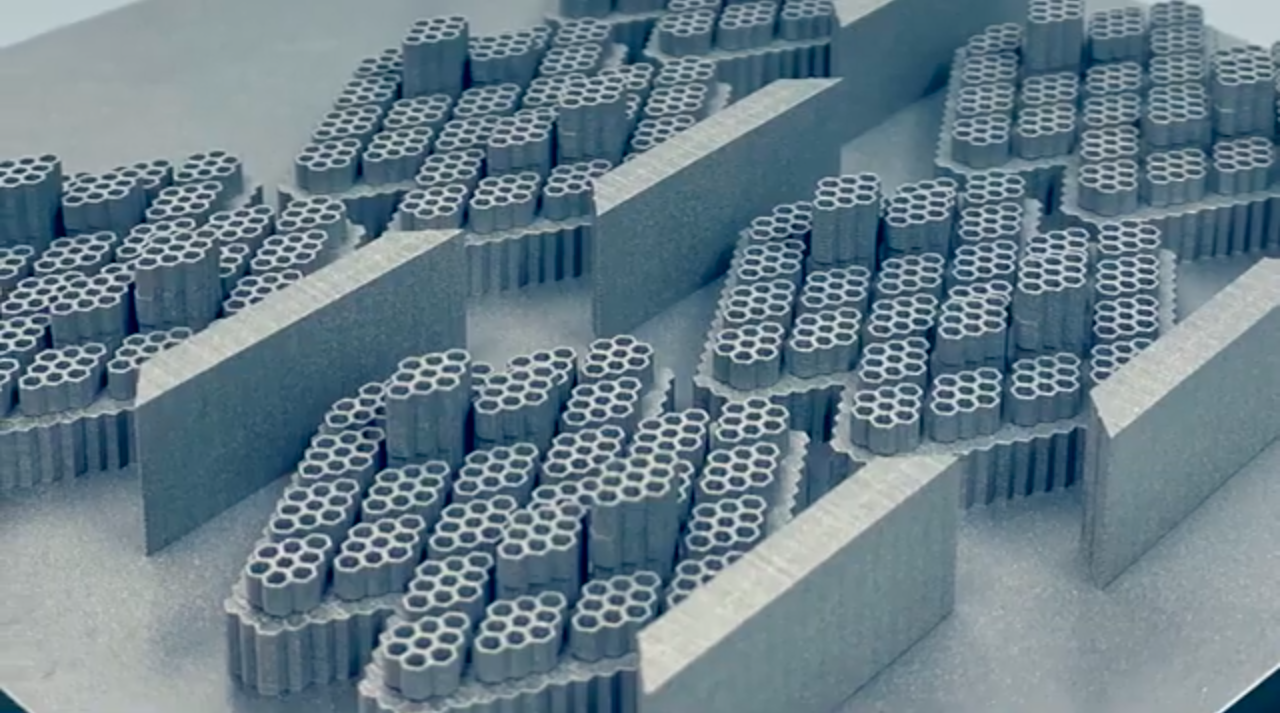

Seurat’s production technology is termed Area Printing and utilizes what it calls Optically Addressed Light Valves (OLAVs). “Every pixel at the OALV defined its laser spot, effectively creating a profusion of individual lasers out of one very powerful laser” that endeavors “laser light to a bed of alloy powder, then weld a darkened region within a minute, and build up a multi-layer part. ” If you set it like this, it sounds a hell of a lot more such as Mondriaan, correct?

By illuminating an whole print bed layer at one time, Seurat dominates the point that those machines invest 60% of their time recoating, however this can be a hugely exciting development none the less. By decreasing the scan time of their laser, assembles can be processed substantially faster, such as high speed sintering (HSS) for polymers and other diode and array laser projects .

Seurat’s approach is a basic challenge to the existences of present powder bed combination (PBF) businesses. EOS was operating on a similar technology because 2013, however no one knows when or when they’ll pull it off. Their VCSEL strategy could provide similar consequences . If we contrast the multi-laser approaches to Seurat’s, however, the latter will be considerably cheaper to implement with less sophistication and higher rates.

Seurat currently has $33 million to apply this technology which doesn’t look considerably awarded the challenges in commercializing OALV along with the system for printing printing. The business first printed metal components from 2015 and contains just come out of stealth mode. Presumably Desktop Metal’s inventory transfers , the proposed SPAC of Markforged, along with the consequent interest in ExOne along with voxeljet makes currently a very opportune time to get a metal 3D printing firm to be trying to find money.

Its too early to tell when Seurat is going to be able to commercialize its technologies successfully. It’s extremely tricky to go from a technology into a production machine which works well in an industrial setting. Velo3D has really been able to do this but it’s far from facile. Co-founder and CEO James DeMuth created the technologies at Lawrence Livermore National Laboratory and worked together with Erik Toomre who was at Tesla, Volkswagen and Sun to build up the firm. The Chief Scientific Officer Andy Bayramian worked at Lawrence Livermore for over 24 years as a physicist and has coauthored a whole lot of newspapers that melt my mind on lasers and far more besides. The VP of Engineering lead four firms to IPO. Partners include Denso, Porsche, GM, and Siemens together with Porsche and GM having invested in the firm Also. There is a lot of pedigree and promise within this business.

Their guarantees will even fundamentally change our industry if they can be accomplished. The business points to “precise laser power management in space and time provides complete excellent management ” and “by melting cleanly, average part size limitations will likely be defeat ”. At precisely the same period, Suerat asserts the “precision and surface finish combine to empower authentic net-shape processing. ” The business expects to reach a whole great deal of considerable sea change-type performance enhancements for the technology concurrently. Should they do it, we will be a lot nearer to 3D printing cheap parts for industry and lots of other businesses will probably be dead in the water. That is a large “in case ”, though.

The technology is actually more of a Seurat-meets-Jackson-Pollock. Sad that they didn’t move for JacksonAt or even SeurOllock. I’m thankful that they didn’t pick another pointillist, Pissarro, because that could be problematic for everybody to spell and you also ’d have to explain all the time that, ‘yes they’re ambitious’ although perhaps not conquistador-ambitious. Henri Delavallée is probably out, because of spelling also. Many will google “Del valley” and end up at a house testimonials company by error .

Although I love Theo van Rysselberghe, I might imagine that name would likewise be suboptimal as a catchy startup brandnew. Think about their bad secretary. Toorop sounds really cool, and I can not fathom why they didn’t choose that. I’m positively confident that they didn’t choose Hippolyte Petitjean who’s, though undeservedly, not as known, has one of my favorite titles ever. I could just imagine the dismay as this American business was turned down by the still-living American pointillist Chuck Close, that possibly has the best name in all of painting.

I believe Signac are a wonderful choice, perhaps something to consider if you’d love to contend with Seurat. It would be far nicer to get a bevy of impressionists specify our industry compared to rather macho tech-heavy titles we have today.

The article Seurat Aims to Disrupt Metal 3D Printing with two Million Lasers appeared on 3DPrint. com | The Voice of 3D Printing / Additive Manufacturing.

Article Source and Credit 3dprint.com https://3dprint.com/279567/seurat-aims-to-disrupt-metal-3d-printing-with-2-million-lasers/ Buy Tickets for every event – Sports, Concerts, Festivals and more buytickets.com

Leave a Reply

You must be logged in to post a comment.