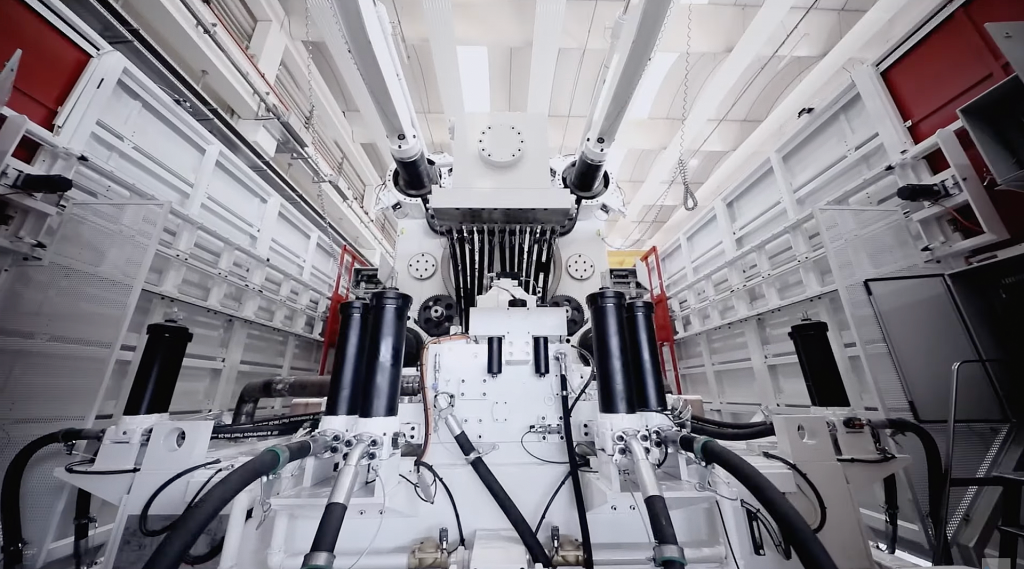

Tesla’s next generation of automobiles will be constructed on the back of the Giga Press, a system capable of producing massive, single-piece casts for crucial components like an electric car’s rear underbody. At a recent movie, IDRA, the company constructing the house-sized die-casting contraptions, shared some tips about the menacing machine’s development, its advantages, and its forthcoming iterations such as the 8,000-ton Giga Press that will be used for the Tesla Cybertruck.

At a recently published video, IDRA General Manager Riccardo Ferrario explained the Giga Press is especially made to be environmentally-conscious as you can. Developed over many years, the Giga Press could supply automakers with several key advantages, such as less investments, less handling of parts, better quality, less energy consumption, and reduced CO2 emissions. Consequently, all these are things which are incredibly important to a company like Tesla, that has shown itself as the frontrunner at the sustainable transportation movement.

#GigaBerlin #Gigapress An important announcement from the IDRA  Group General Manager.” What is GIGAPRESS and wich are GIGAPRESS innovative goals”two of these are already assembled on the GIGABERLIN. https://t.co/IWtPOzuQhT pic.twitter.com/pscXGmqm27

Group General Manager.” What is GIGAPRESS and wich are GIGAPRESS innovative goals”two of these are already assembled on the GIGABERLIN. https://t.co/IWtPOzuQhT pic.twitter.com/pscXGmqm27

— @GF4Tesla

.build #GigaBerlin. (@Gf4Tesla) April 1, 2021

.build #GigaBerlin. (@Gf4Tesla) April 1, 2021

(adsbygoogle = window.adsbygoogle || []).push({});

Similar to Tesla’s electrical car lineup, the Giga Press family is simply getting started. As explained by the executive, IDRA is still looking to enlarge the Giga Press family, and lately, the company was able to do exactly that. Only last month, Ferrario commented that IDRA obtained the very first order because of its largest machine nonetheless –an 8,000-ton Giga Press specially made to produce parts for larger vehicles such as pickup trucks and SUVs.

The IDRA executive did not name its customer for the order, however all signs are pointing into Tesla, a company which has already purchased numerous 6,000-ton Giga Presses from the Italian business. Tesla CEO Elon Musk has also noted the Cybertruck’s rear underbody would be made by an 8,000-ton die-casting system , which is significantly larger compared to Giga Presses utilized for the Model Y.

“We have improved our variety of machines to encompass another world –an 8,000-ton die-casting press. And it is with terrific pride that I can declare, we have achieved it. It’s not only a dream or drawings . It’s currently reality. In fact that IDRA and the team supporting the Giga Press have been in a position to perform in a really short space of time following the rather high demand of our customer from all around the globe.

“The first-ever order to get an 8,000-ton device has now been obtained in March 2021. We’re so enthusiastic about accepting the idea of the Giga Press a step farther and applying it directly into the SUV and truck market, which is a place, until today, not fully explored. Total electric trucks for transportation of goods utilized by companies like DHL or Amazon can expand the market of Giga Press,” the IDRA General Manager said.

Tesla is currently putting the pedal to the metal on the construction of Gigafactory Texas, where the Cybertruck would be made. As such, IDRA would have to place in a great deal of effort to make certain it can deliver its largest machine to date punctually. In case the executive’s content is any indication, but it appears that IDRA is just as eager to drive the limits of the die-casting industry as far as Tesla is eager to push the limitations of electric cars. This suggests the 8,000-ton Cybertruck Giga Press may make it into Giga Texas in just the perfect time for the start of the all-electric pickup truck’s production.

View IDRA’s newest movie on its own Giga Press machines from the movie below.